2017 so far has seen Nixons invest in new personnel, factory extensions, new office areas, machinery and we are still investing! This is to keep up with demands within the kitchen industry and ensure we stay market leaders in both quality and in the design of our products.

Our latest investment was the installation of 3 new machines within the factory. These machines are designed to save on space, improve efficiency, accuracy and ensure ongoing quality. By making and assembling our own kitchen cabinets and most of our doors, we are able to own the entire process of creating your dream kitchen. This means that we have full control over the quality of your new kitchen.

So what do our new machines do?

The BHX 050: Our new boring machine is used to drill holes into cabinet material for e.g. shelf pegs dowels or other connectors, it can also be used to router grooves and trim down materials.

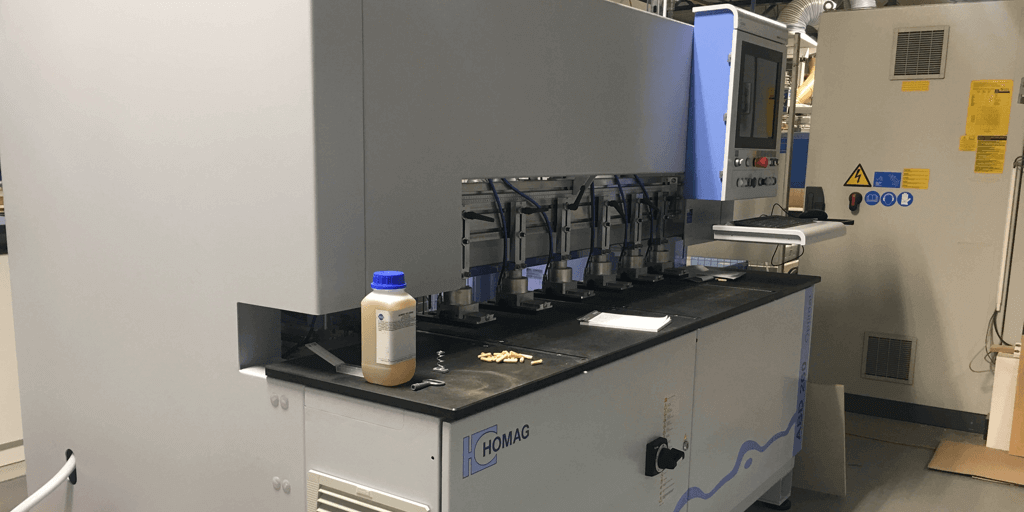

The ABD 260: This machine sits next to our existing CNC machining centre. This machine is used for horizontal drilling, gluing and dowel insertion. Increasing efficiency by minimizing set-up times and maximizing production times, the ABD drills, glues and inserts dowels within seconds speeding up our efficiency within the factory.

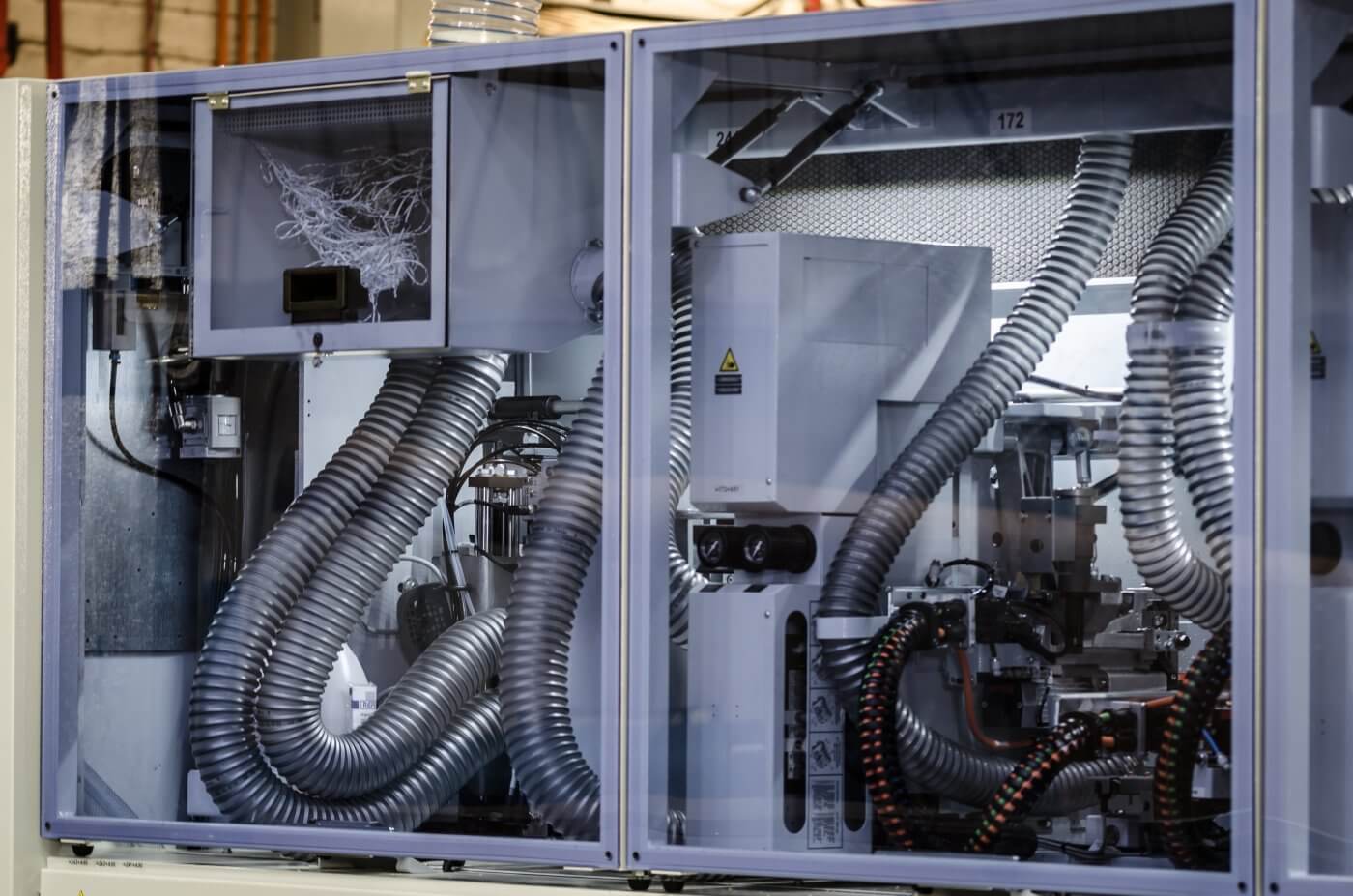

The Ambition 2470: Predominantly used for edge banding. Edgebanding is a process used to cover the raw ends of materials, glueing and then finishing the edge. The machine allows for precision and a pristine finish including handling High Gloss materials. The machine features a finish processing unit that comprises of a glue joint scraping unit for disposal of glue residues at both the top and bottom of edges ensuring our quality is continuously improved at Nixons.